Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

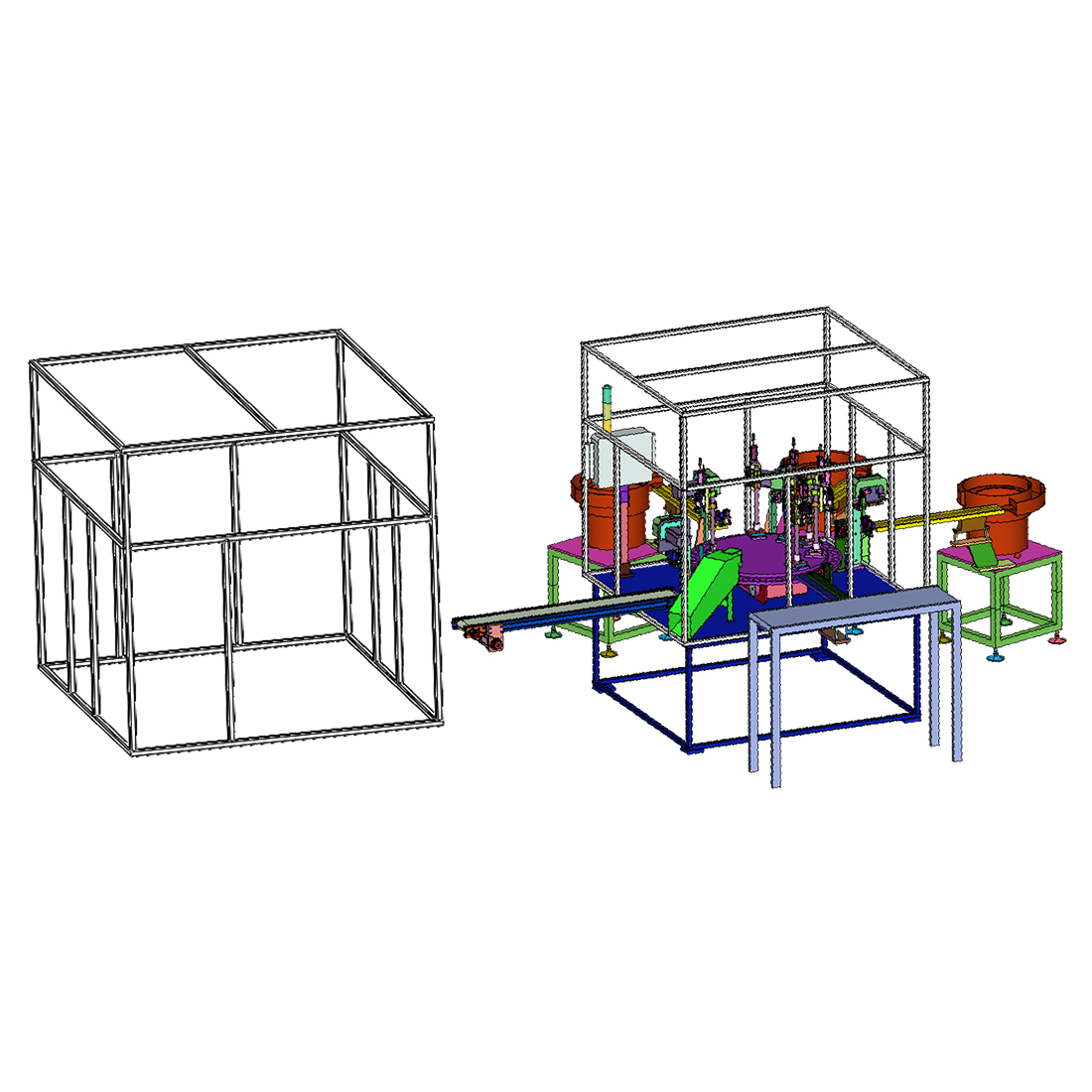

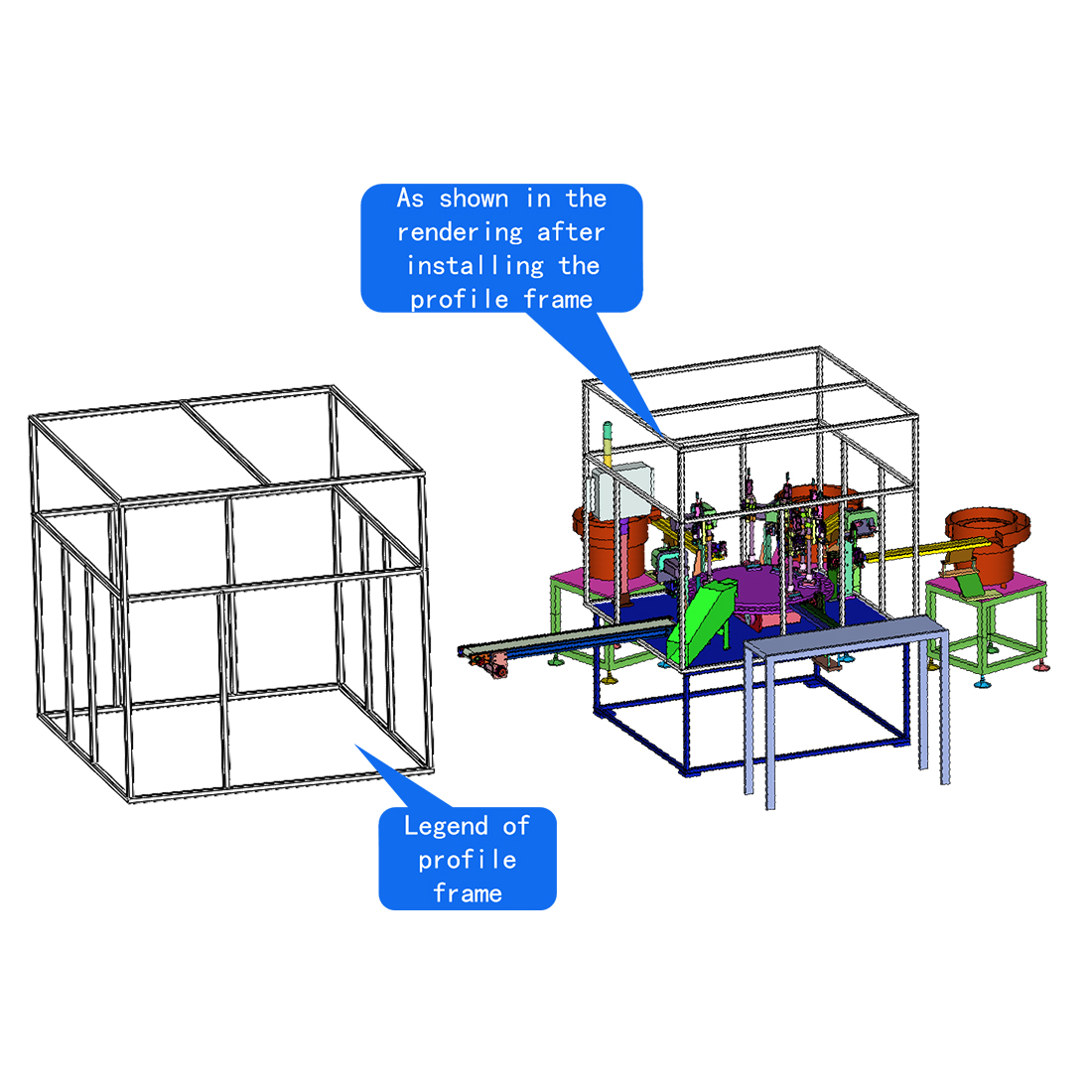

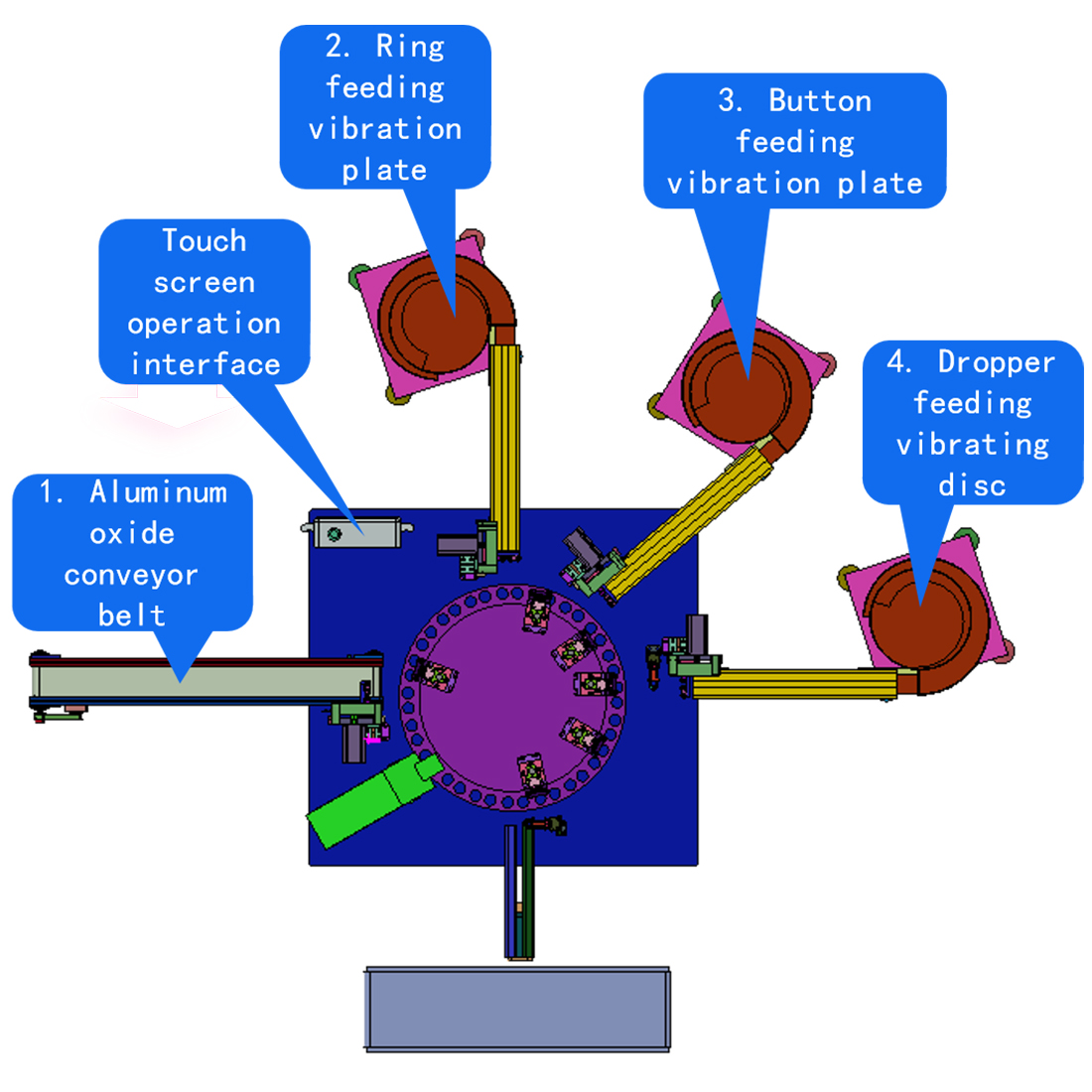

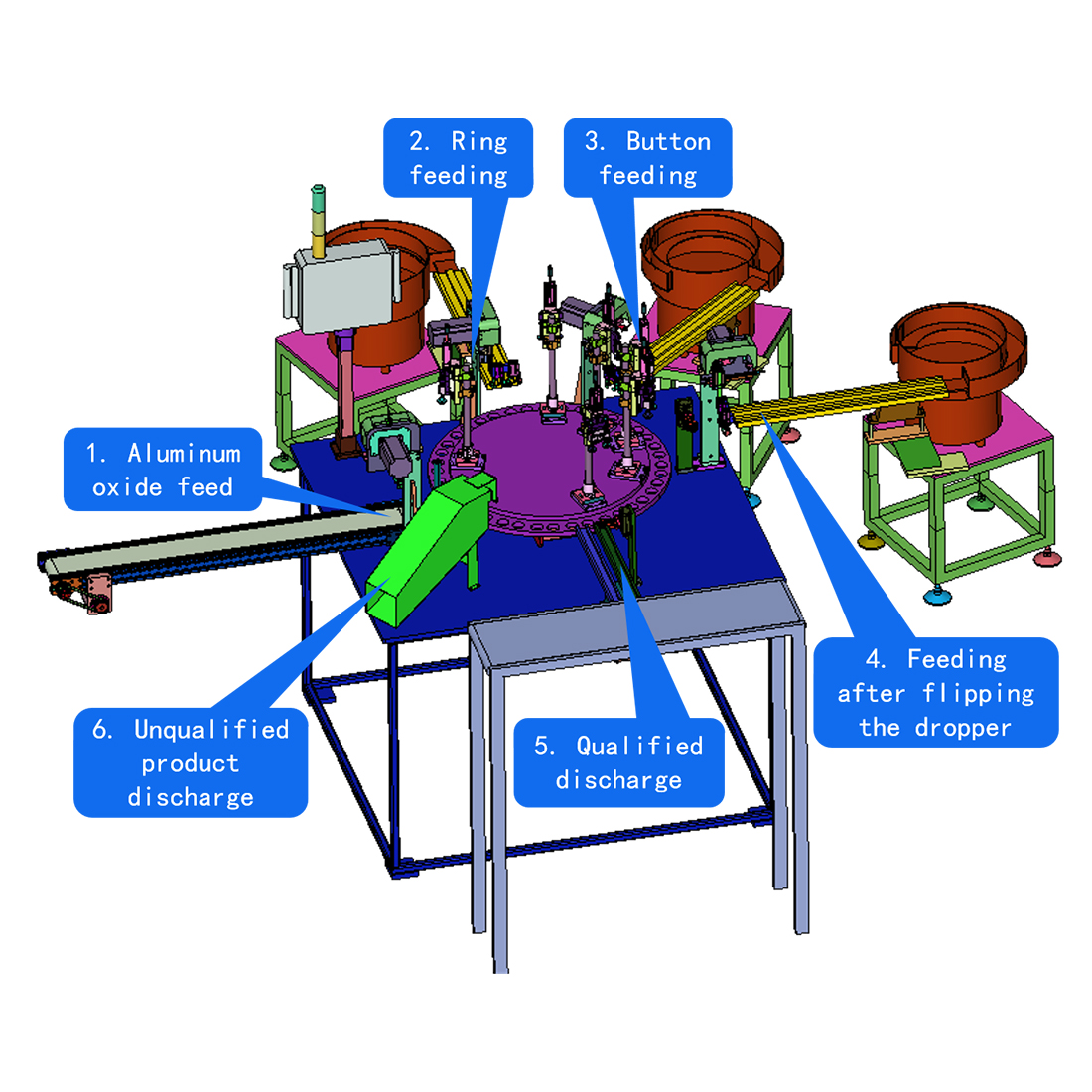

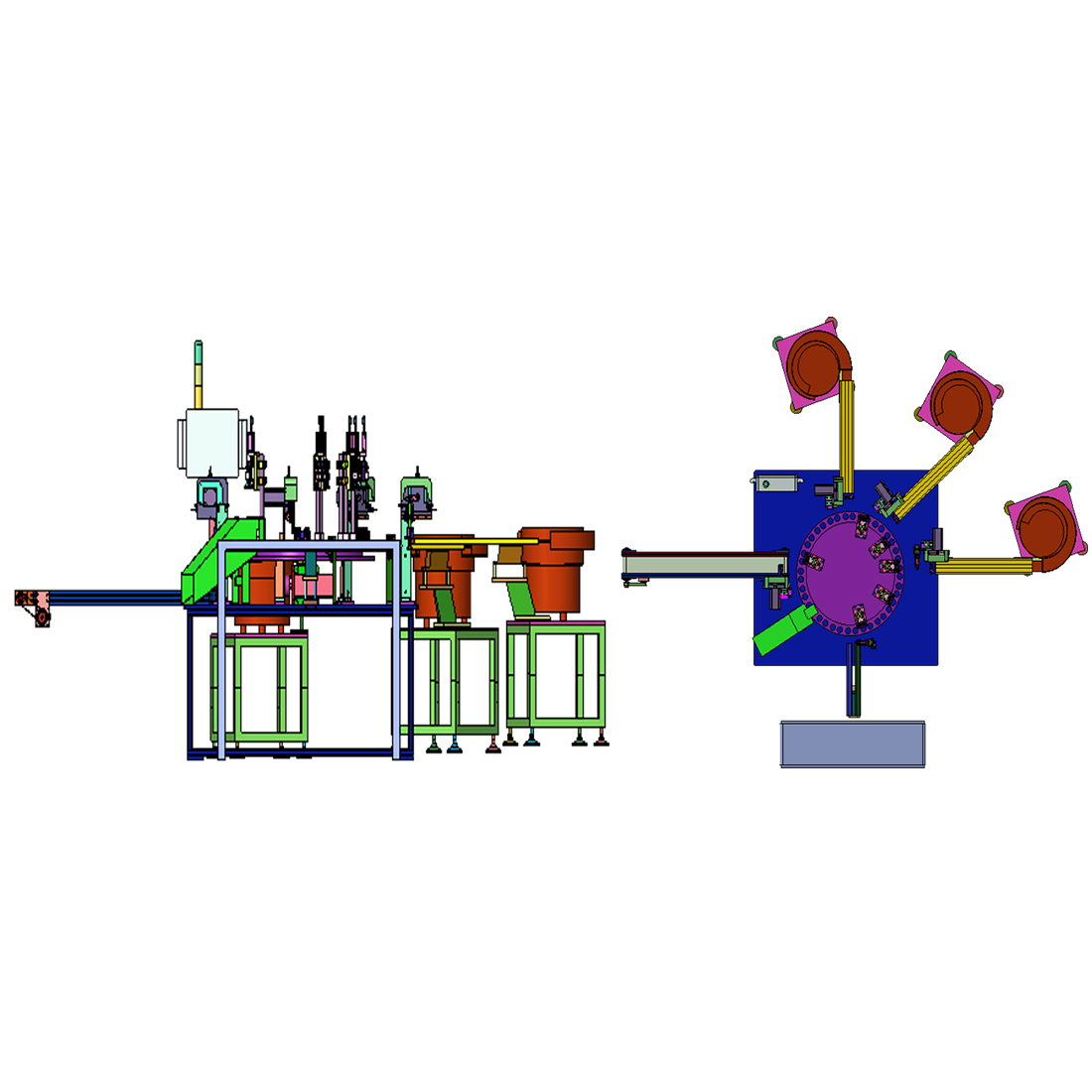

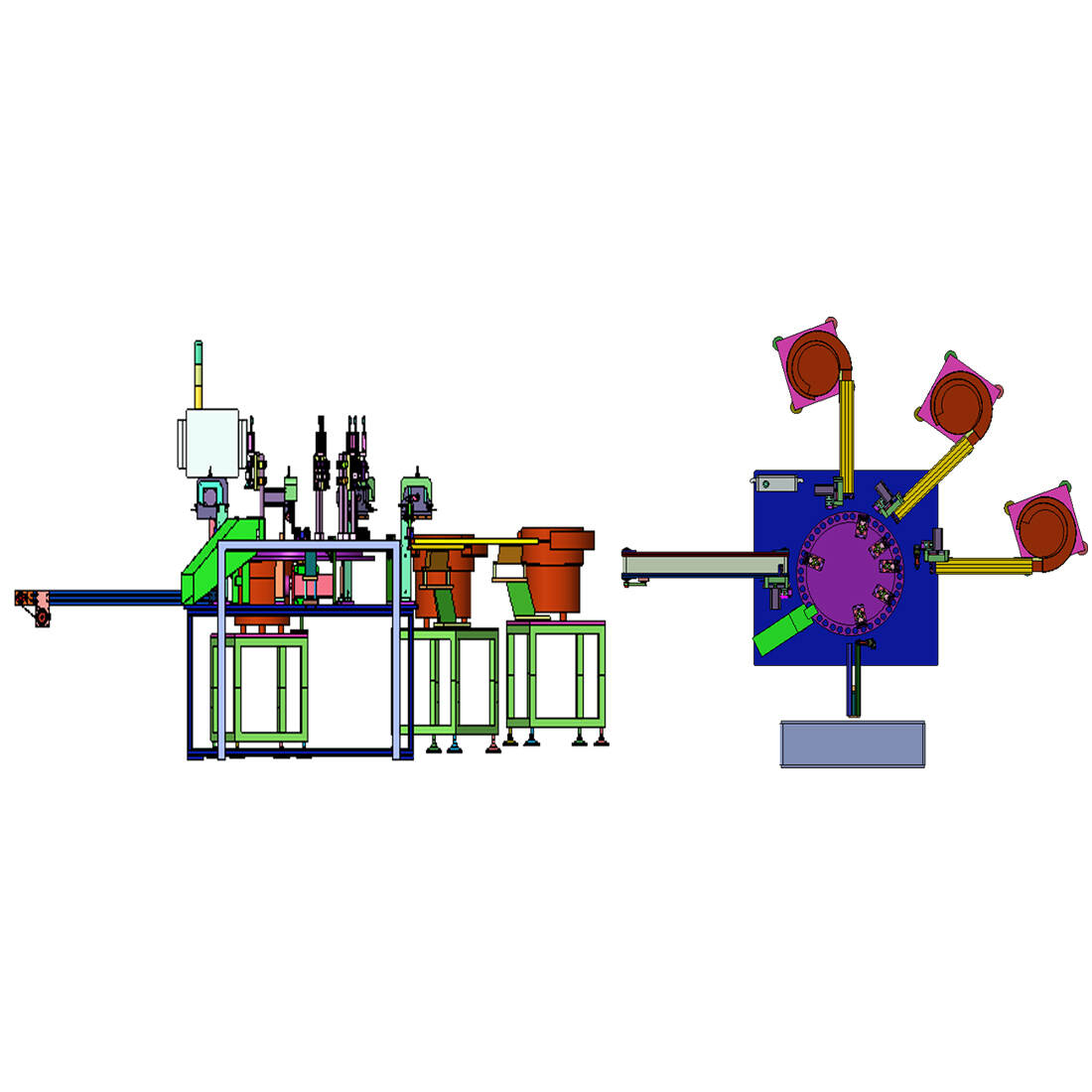

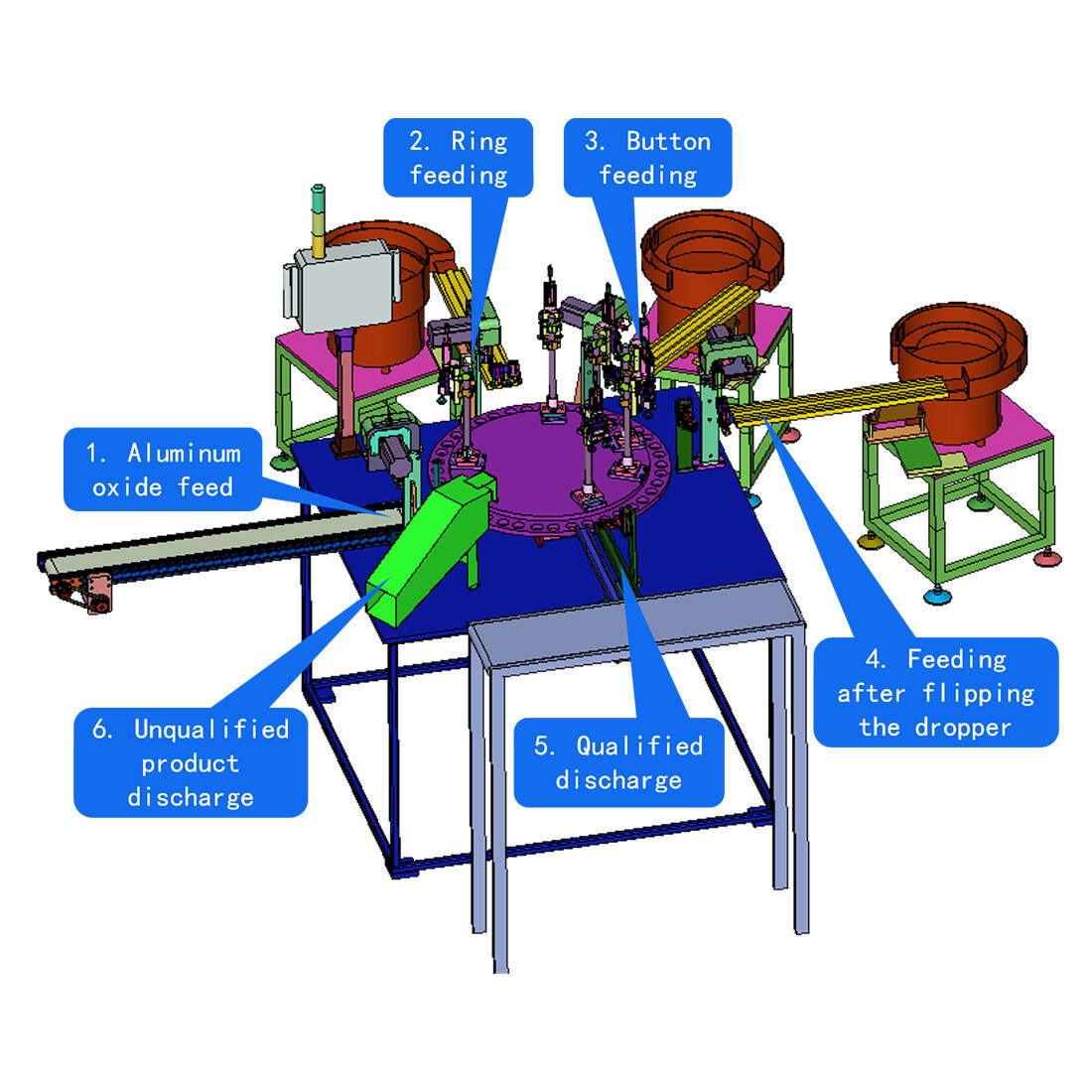

Dropper 3-Assembly Equipment

Dropper 3-assembly equipment

Voltage: 220V

Power: 3.8KW

Air Pressure: 0.6Mpa

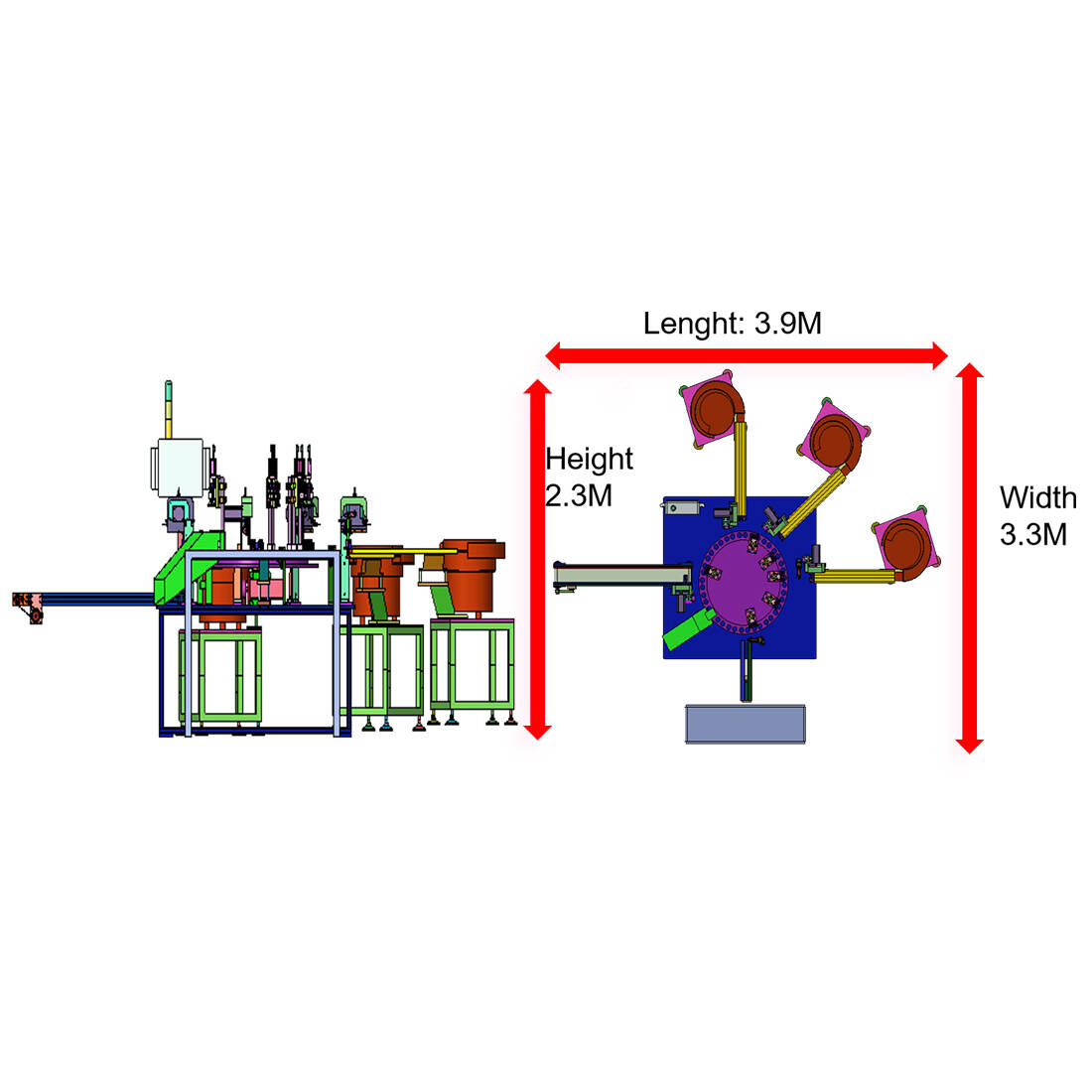

Machine L*W*H: 3.9*3.3*2.3

Capacity/min:

Description

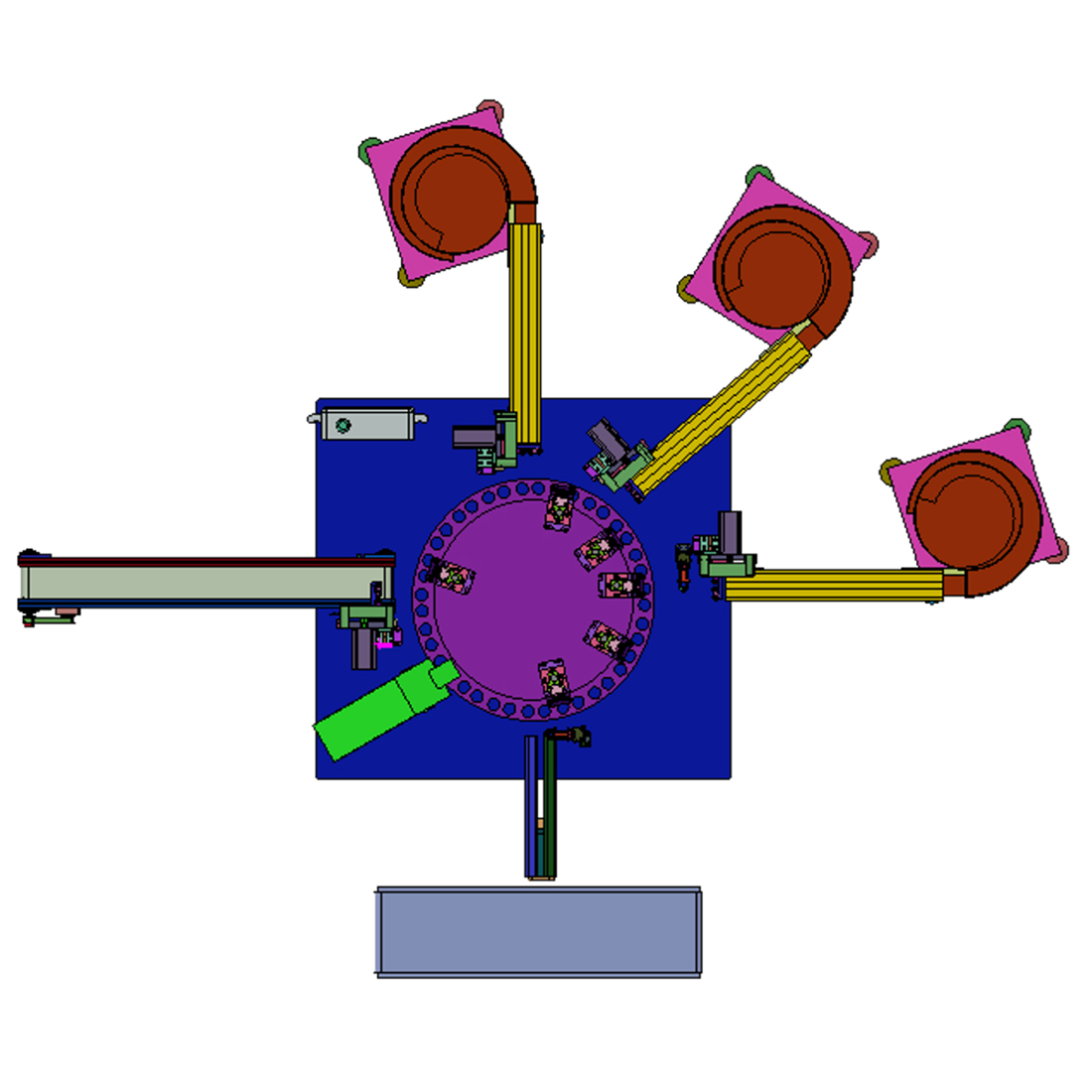

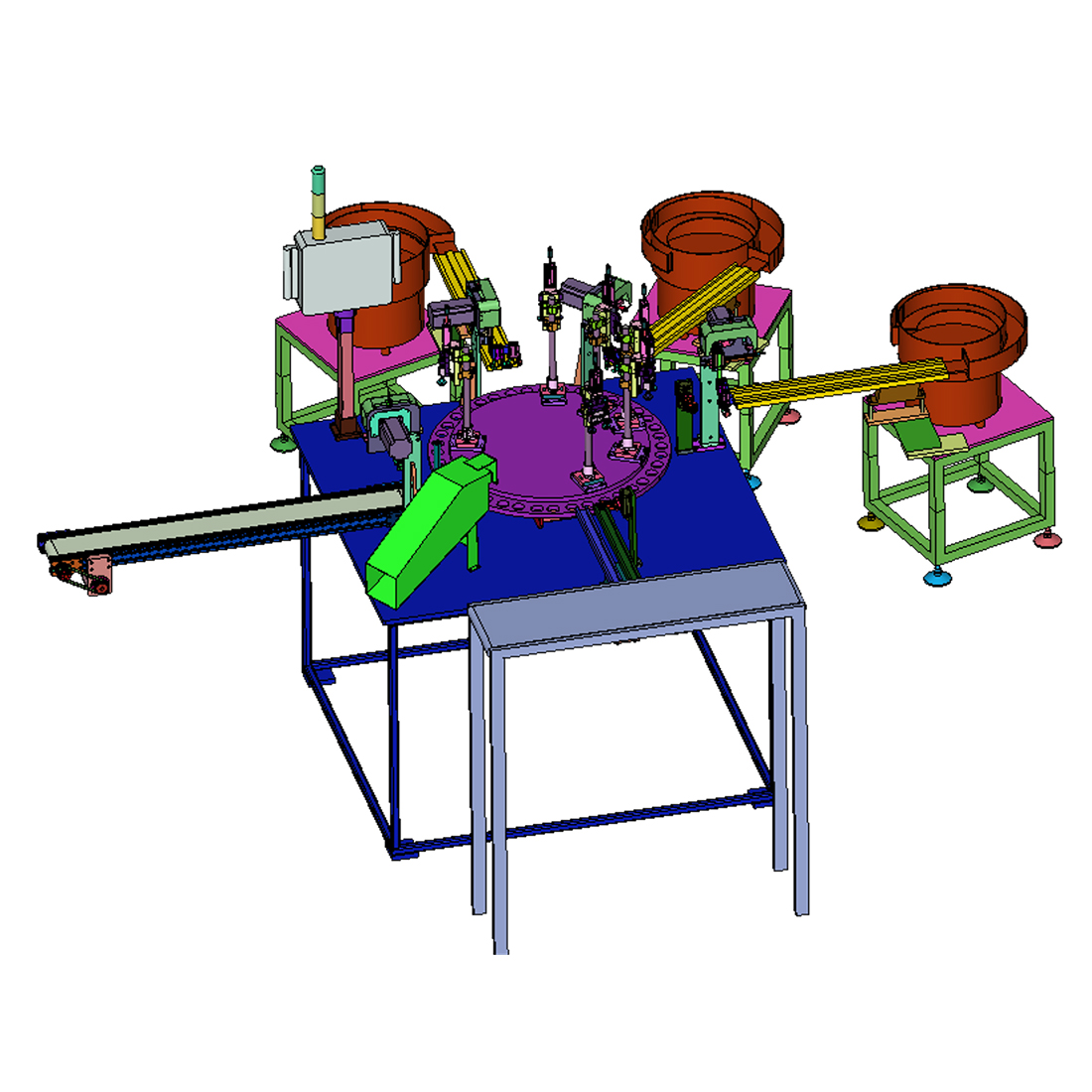

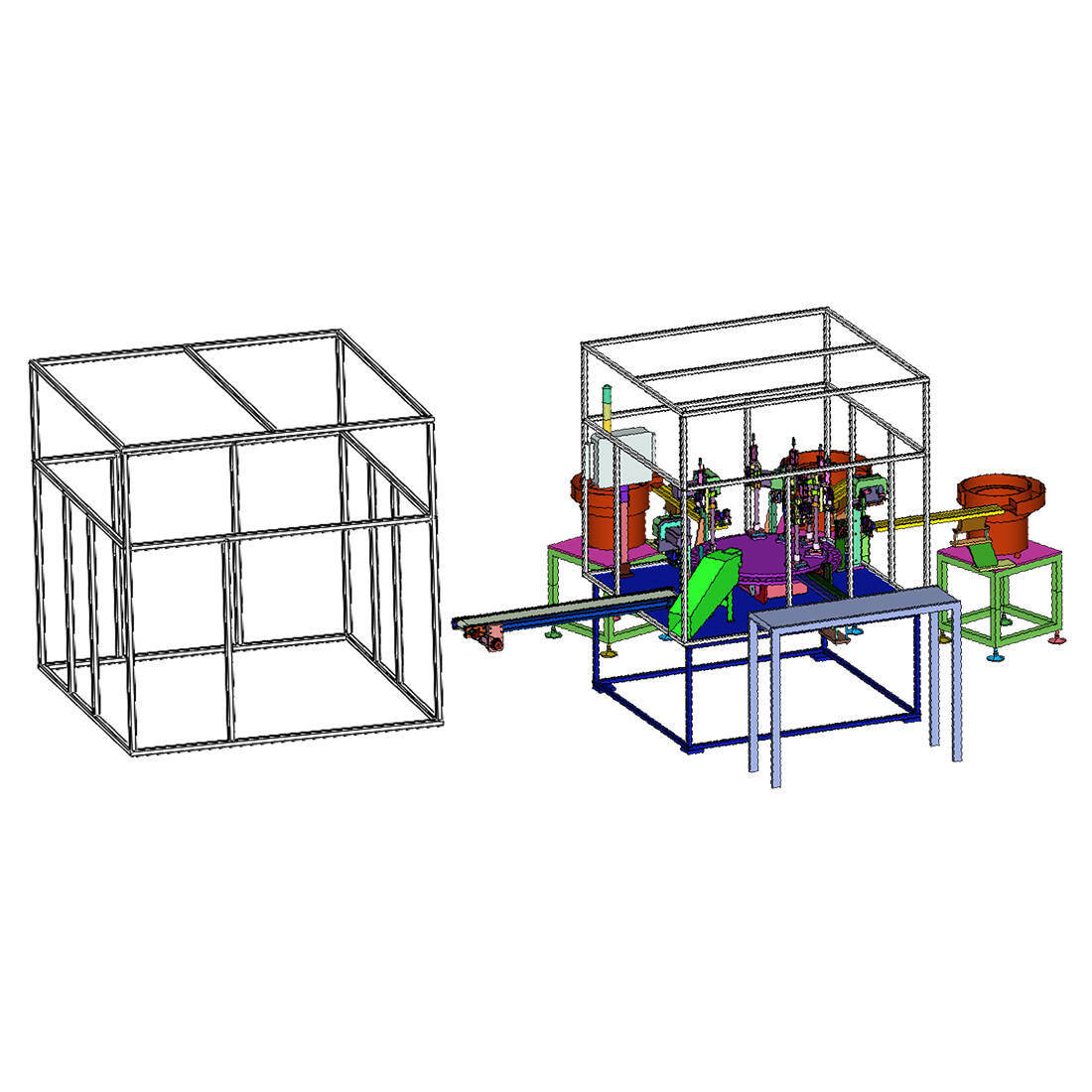

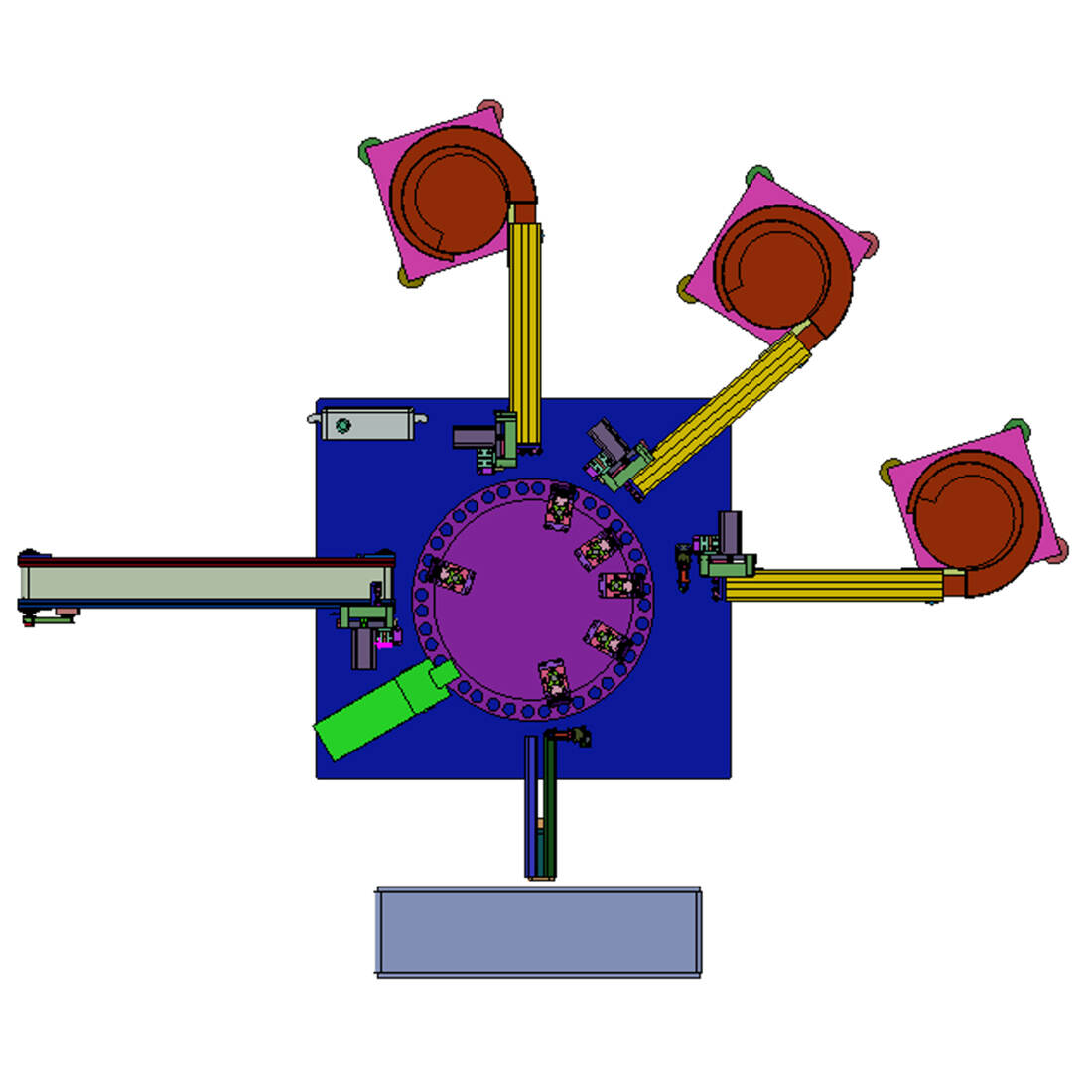

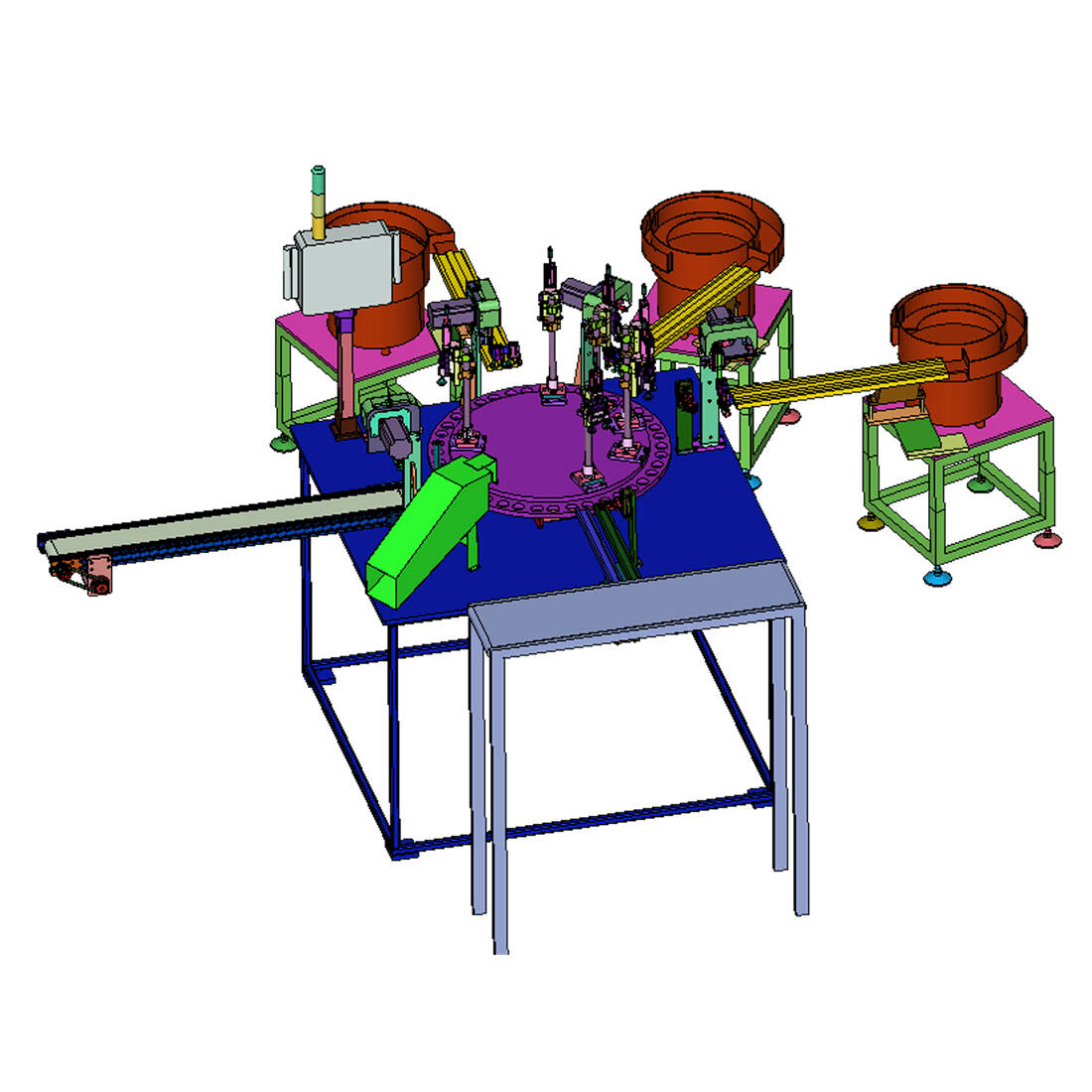

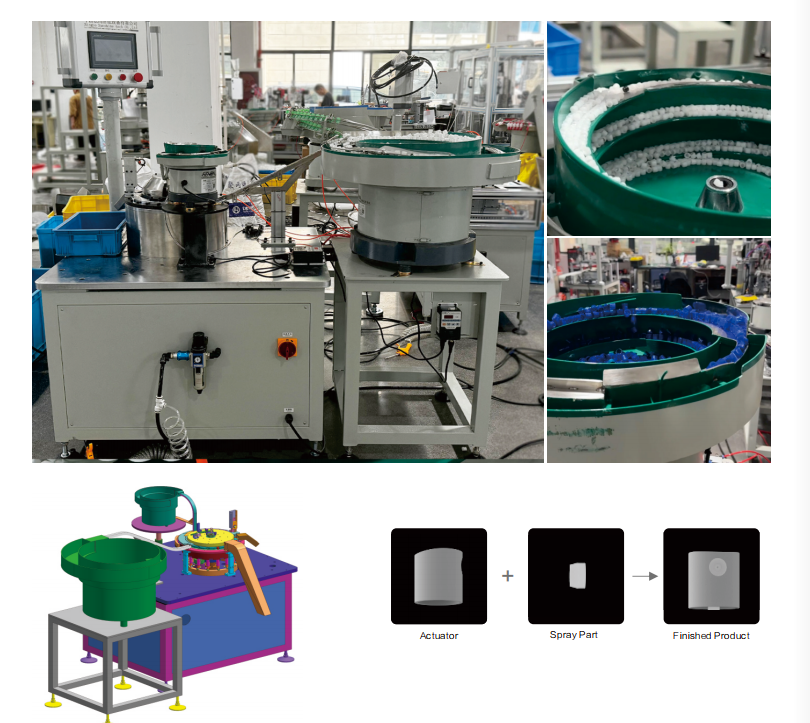

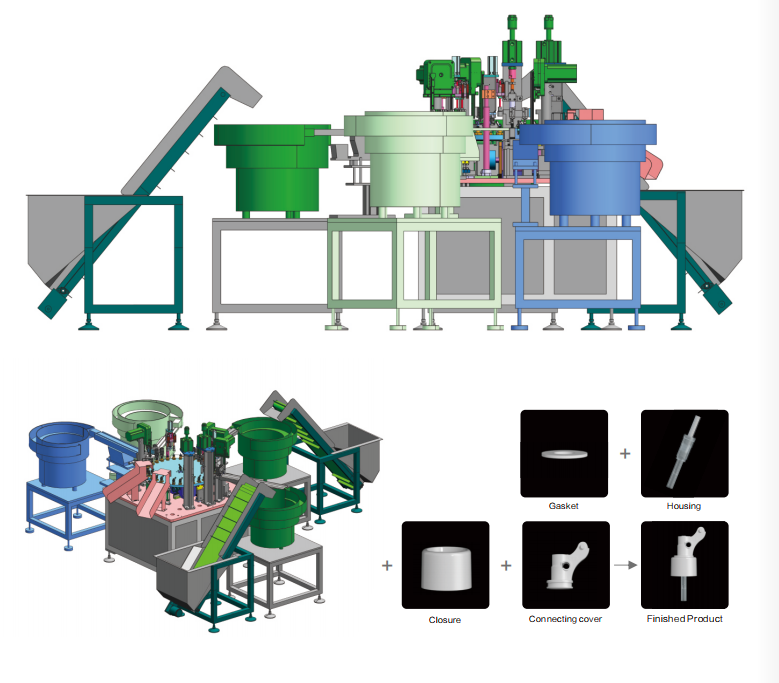

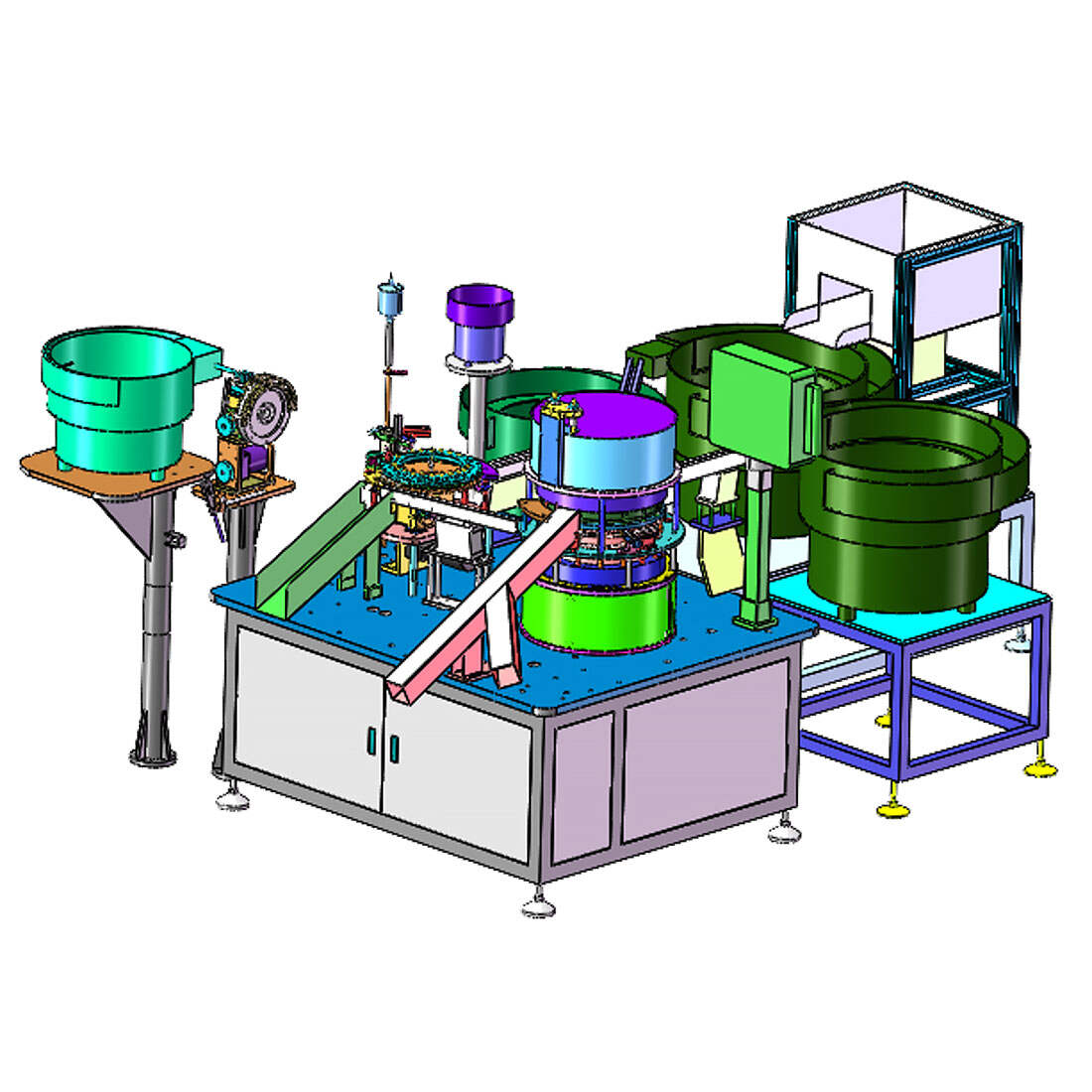

The Dropper 3-Assembly Equipment is a state-of-the-art machine designed for the efficient assembly of dropper components, including the trigger sprayer cover and tube insert. With a total length of approximately 3.9 meters, a height of about 2.3 meters, and a width of around 3.3 meters, this equipment is compact yet robust, fitting seamlessly into various production environments. It is engineered to provide precision and high productivity, ensuring consistent quality in the assembly process.

Product Specification

- Voltage: 220V

- Power: 3.8KW

- Air Pressure: 0.6Mpa

- Machine L*W*H: 3.9*3.3*2.3

Product Features and Advantages of Dropper 3-assembly Equipment

- High Precision Assembly: The machine is equipped with advanced technology that ensures each component is assembled with high accuracy, reducing errors and ensuring a perfect fit for each trigger sprayer cover and tube insert.

- Flexible Operation: The Dropper 3-Assembly Equipment can handle various sizes and types of components, providing flexibility for different production requirements. This versatility makes it ideal for manufacturers with diverse product lines.

- High Speed and Efficiency: With a streamlined assembly process, the machine significantly boosts production speed, enabling higher output rates. Its efficient design reduces cycle times, allowing for a faster turnaround.

Benefits

1. Increased Productivity: By automating the assembly of trigger sprayer covers and tube inserts, the equipment drastically improves production efficiency. This automation allows manufacturers to meet high demand with consistent quality.

2. Cost Savings: The precision and reliability of the machine reduce waste and rework, leading to significant cost savings. Additionally, the robust design lowers maintenance expenses and prolongs the equipment's lifespan.

3. Enhanced Quality Control: The high accuracy of the assembly process ensures that each product meets stringent quality standards. This consistency helps in maintaining brand reputation and customer satisfaction.

4. Time Efficiency: The machine's high-speed operation shortens production cycles, enabling quicker delivery times. This efficiency helps manufacturers respond promptly to market demands and stay competitive.

The Dropper 3-Assembly Equipment is an investment in advanced manufacturing technology that promises to enhance productivity, reduce costs, and ensure high-quality output. Its blend of precision, efficiency, and flexibility makes it an indispensable tool for modern production facilities.